If the engine has been run with an active Cummins Fault Code 3582, then it is likely that a power derate will also be active (Fault Code 3714 – Engine Protection Torque Derate – Condition Exists).

Troubleshoot 3582 first. Once it’s gone inactive, the derate will also go inactive.

How is the SCR Conversion efficiency determined?

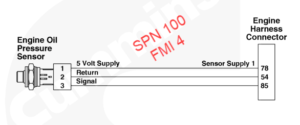

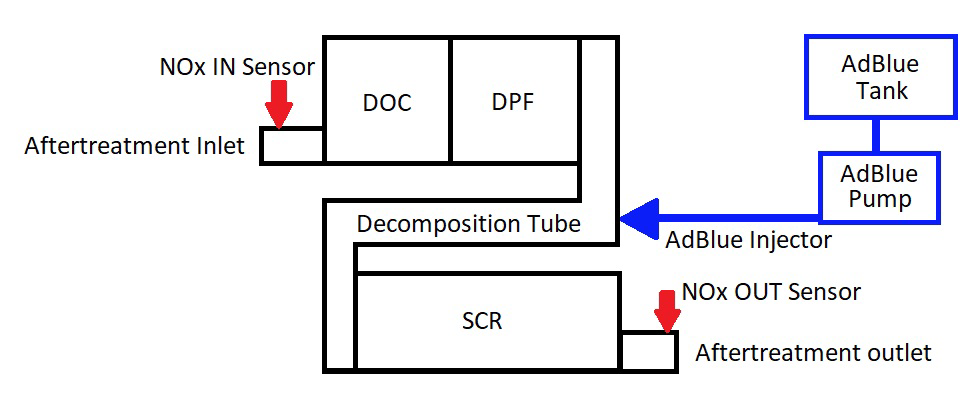

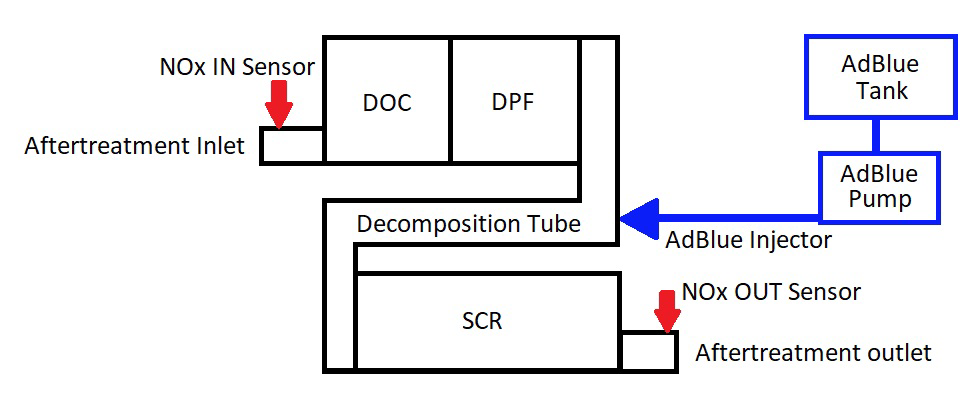

The NOx concentration in the exhaust gases is monitored by two sensors: NOx IN and NOx OUT. The ECM compares these two values, which allows it to determine the conversion efficiency of the SCR catalyst and DEF (AdBlue) dosing system.

Possible causes of Cummins Fault Code 3582

Typical causes that lead to an active 3582 fault code are:

- Malfunctioning AdBlue dosing system

- Exhaust system leaks

- Malfunctioning SCR catalyst

- Bad diesel exhaust fluid quality

- Diesel exhaust fluid deposits in the decomposition tube

- Engine has been running on non-Ultra-low sulfur Diesel fuel leading to catalyst coating deterioration

Where do I find the relevant components?

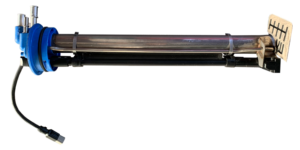

The NOx IN sensor is located either right after the turbocharger, or at the intake of the aftertreatment system. The SCR Catalyst is the last canister of the Aftertreatment system and at the end of it, you will find the NOx OUT sensor.

For the DEF system, the tank location varies depending on application and manufacturer (eg. bus or machinery such as cranes), as well as the AdBlue pump. If you start at the tank, then the pump will be easy to find. Just follow the lines. The AdBlue injector is mounted on the decomposition tube of the Aftertreatment system.

Here is a typical layout of a Cummins Aftertreatment system:

How to troubleshoot Cummins Fault Code 3582

There is no straightforward solution in troubleshooting Fault Code 3582. You will have to go through ALL the steps even if you find things to be out of specification.

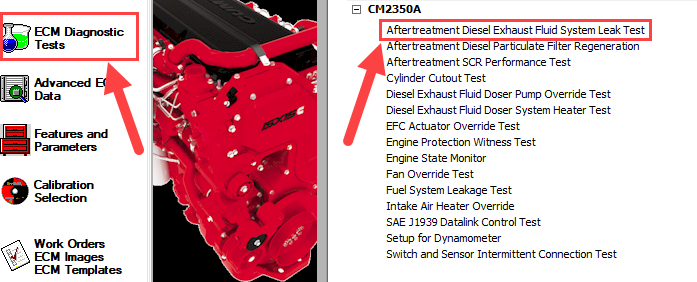

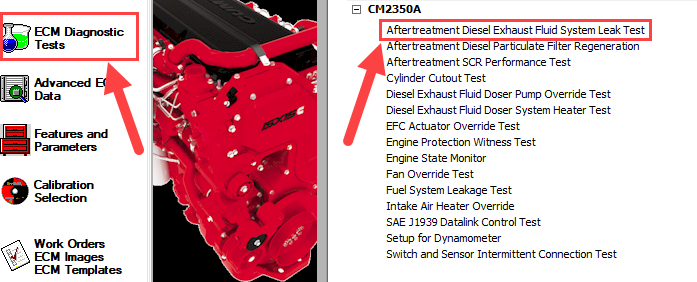

Please note that you won’t be able to perform the diagnostic procedure, unless you have Cummins Insite or an equivalent tool, such as TEXA.

Step 1:

Important: Before you start troubleshooting Fault Code 3582, troubleshoot all other SCR or AdBlue system related faults first.

Connect your diagnostic tool and read all the active Fault Codes or Fault Codes with more one inactive count in the last 25 operating hours.

If you find any, troubleshoot them first and then continue to Step 2.

Step 2:

Ensure AdBlue is not contaminated.

- Check the tank for debris and contamination.

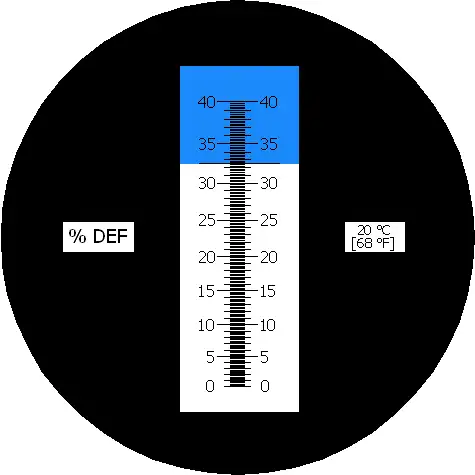

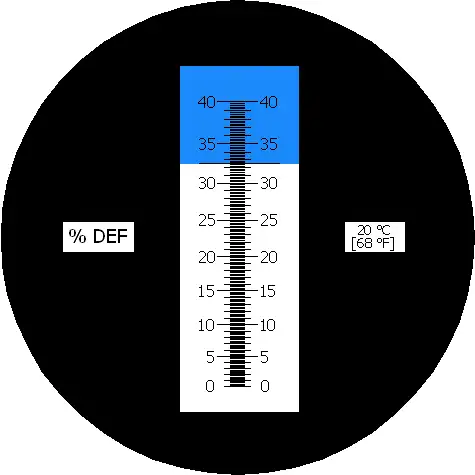

- Use a refractometer to check the fluid. You are looking to get a reading of 32.5% ± 0.7%.

If AdBlue is out of specification, or dirt is found in the tank, drain and clean the tank, then refill it with fresh AdBlue. Continue to the next step.

Step 3:

When the engine runs and exhaust gases flow through the Aftertreatment, the system is under slight pressure. Leaking gaskets or connections allow exhaust gases to escape, affecting system temperatures.

If the leak is happening at the injector area, then AdBlue can leak out of the system with the escaping gases, or can cause turbulent flow in the decomposition pipe. Bad flow in the pipe can force AdBlue to sit on the walls and drip down, instead of mixing with the gases. This can cause internal blockages due to crystalization.

On this step you need to perform mostly visual inspections. Inspect the exhaust piping for leaks, cracks, and loose connections:

- Check for leaks between Engine head and Exhaust manifold

- Check for leaks between Exhaust manifold and Turbocharger

- Check plumbing between Turbocharger outlet and Aftertreatment DOC intake connection

- Inspect for leaks at all sensor ports on the whole system

- Check all canister connections and clamps (DOC to DPF, DPF to Decomposition pipe, Decomposition pipe to SCR inlet, etc)

Repair or replace any components that allow exhaust gas leakeage and move on to step 4.

Step 4:

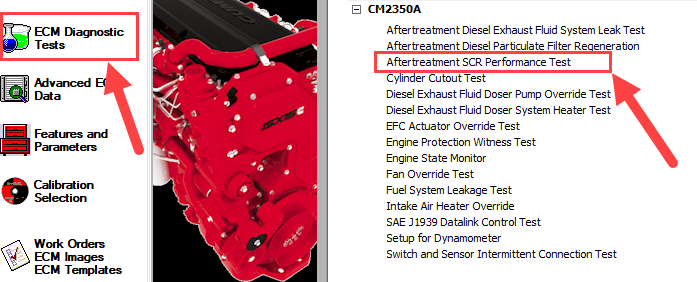

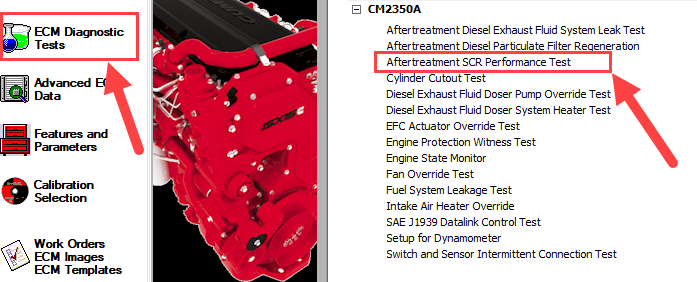

Cummins Fault Code 3582 is becomes active if the SCR System performance is low. Luckily, Cummins Insite, TEXA and a few other equivalent tools, will allow you to start an “Aftertreatment SCR Performance test”.

This test runs for 60 to 80 minutes and is really noisy, so be prepared for it. It is best to perform it outside, otherwise ensure you use an exhaust extraction system that can handle high temperatures.

In case the test fails right after it starts, a reason will be displayed on the screen. Correct the issue and restart the test.

Some example failure messages are:

Coolant temperature too low: There is an initial warm-up period when the test starts. If the timer expires and thhe temperature is too low, then the fault is displayed. Turn the Key-Switch off and then on again. Restart the test.

Active Fault Codes: Troubleshoot the active Fault Codes and restart the test.

Clutch or Service Brake is depressed: Ensure the OEM switches and circuits are in good condition and that there is no operator input during the test (otherwise the test stops due to safety reasons).

When the SCR Performance Test is running, the following sub-systems are evaluated:

- Aftertreatment Warm Up and DEF Dosing System Test

- Aftertreatment SCR Deposit Burn Test

- Aftertreatment NOx Sensor Rationality Test

- Aftertreatment SCR Catalyst Test

During the test, you can see the status of each test. If the sub-tests fail to complete, perform troubleshooting:

Aftertreatment Warm Up and DEF Dosing System Test: Failed

- Check AdBlue for proper concentration (use a refractometer) and the AdBlue tank for contamination.

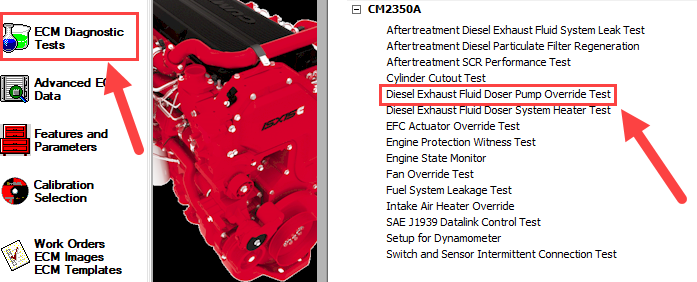

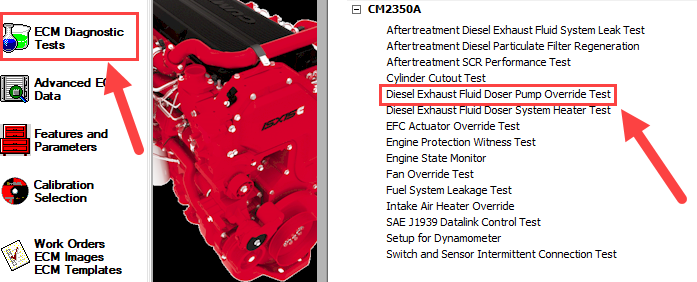

- Use Cummins Insite or TEXA to perform the DEF dosing unit override test (AdBlue Injector flow test)

If the DEF dosing unit override test was successful (check commanded DEF Injection volume during the test), perform the following:

- Inspect the AdBlue pump intake fitting for contamination.

- If debris is found in the intake fitting, replace the fitting and flush the pump. Also drain and flush the AdBlue tank and intake line.

- If intake fitting was clean, replace the AdBlue pump.

- Once you find the root cause and correct it, re-run the SCR Performance test.

Aftertreatment SCR Deposit Burn Test: Failed

This will not affect the test. The test will continue to run. Unless the Aftertreatment NOx Sensor Rationality sub-test fails, you won’t have to repair or inspect the system.

Aftertreatment NOx Sensor Rationality Test: Failed

Here we have three possibilities and their solutions:

1. Aftertreatment intake NOx sensor failed

- Replace the intake NOx sensor.

- Restart the SCR Performance test.

2. Inspect Outlet NOx Sensor

- There is a possibility that the SCR decomposition tube is blocked due to AdBlue crystalization deposits. Inspect the decomposition tube and clean if necessary.

- Use Cummins Iniste or TEXA to run the DEF system leak test. Monitor the AdBlue Injector nozzle for leaks, which could affect NOx conversion efficiency. If the injector fails, replace the AdBlue injector.

- If no DEF deposits are present and the AdBlue injector and supply lines are not leaking, replace the outlet NOx sensor. Afterwards, restart the SCR Performance test.

3. Inspect both aftertreatment NOx sensors

- Inspect the decomposition tube for AdBlue deposits and clean if necessary.

- Use Cummins Iniste or TEXA to run the DEF system leak test. Monitor the AdBlue Injector nozzle for leaks, which could affect NOx conversion efficiency. If the injector fails, replace the AdBlue injector.

- If no DEF deposits are present and the AdBlue injector and supply lines are not leaking, replace both NOx sensors. Afterwards, restart the SCR Performance test.

Aftertreatment SCR Catalyst Test: Failed

Connect Cummins Insite or TEXA and perform the DEF dosing unit override test (AdBlue Injector flow test)

- If the test fails (eg. low AdBlue injected volume), correct the issue and then restart the SCR Performance test.

- If the test is found to be within specification, then the SCR Catalyst must be damaged. Replace the SCR Catalyst and perform the SCR Performance test again.