To better understand how SCR systems work, we need to look at the whole process and take it step-by-step.

How are Nitrogen Oxides (NOx) created?

Combustion in a turbocharged diesel engine uses an excess of air, which means more Nitrogen is present comparing to a non aspirated engine (petrol or diesel – doesn’t matter).

When the conditions in the cylinder are correct (excess of oxygen and high combustion temperatures), bonds are formed between Oxygen (O2) and Nitrogen (N2) molecules. There are two Nitrogen-Oxygen combinations that mainly concern the legislation (and engineers!):

- Nitrogen Monoxide (NO) = 1 Nitrogen atom (N) + 1 Oxygen atom (O)

- Nitrogen Dioxide (NO2) = 1 Nitrogen atom (N) + 2 Oxygen atoms (O2)

To avoid having to write NO and NO2 every time talk about any of these combinations, we typically refer to them as Nitrogen Oxides (NOx). The letter “x” is a numerical indicator of Oxygen molecules and can be replaced with the number 1 for NO (NO1) but it is omitted, or number 2 for NO2.

The formation of NOx during diesel combustion depends on a lot of other factors, but we can generally conclude that it cannot be avoided.

How can we reduce NOx?

NOx formation is directly linked to combustion temperature:

Higher combustion temperatures = high NOx

Lower combustion temperature = low NOx

How to reduce NOx? The easy answer would be to reduce the temperature during combustion and the problem will be fixed! Simple!

Hmm, it is more complicated than that… Here’s a question for you:

What is the fundamental difference between petrol (gasoline) engines and diesels?

If you said “fuel ignition method” you are right!

A diesel engine relies on cylinder pressure and temperature to ignite the fuel. We can fix the NOx problem by dropping temperatures, but then let me ask you another question:

What else depends on combustion temperatures?

Power output!

Internal combustion engines have been in development for more than 100 years now. The pistons are still round, the intake and exhaust valves still there – you get the point. There is not much to improve anymore without sacrificing something else.

However, engineers a few decades ago found a solution to dramatically reduce NOx in the cylinder without the need of expensive and complex systems. Exhaust Gas Recirculation valves (EGR) have the ability to reduce NOx by up to 70% when calibrated properly! I would love to cover the EGR subject in this post, but we will go off topic… I’ll work on another post explaining EGR operation and provide a link soon.

What is an SCR system?

If you already read the text above, it is evident that we care about: increasing power output, while decreasing NOx.

Internal combustion engines are reaching their limits of mechanical development, so improving in-engine components is almost un-economical. So what is left to do?

Fix the NOx problem after the gasses leave the cylinder!

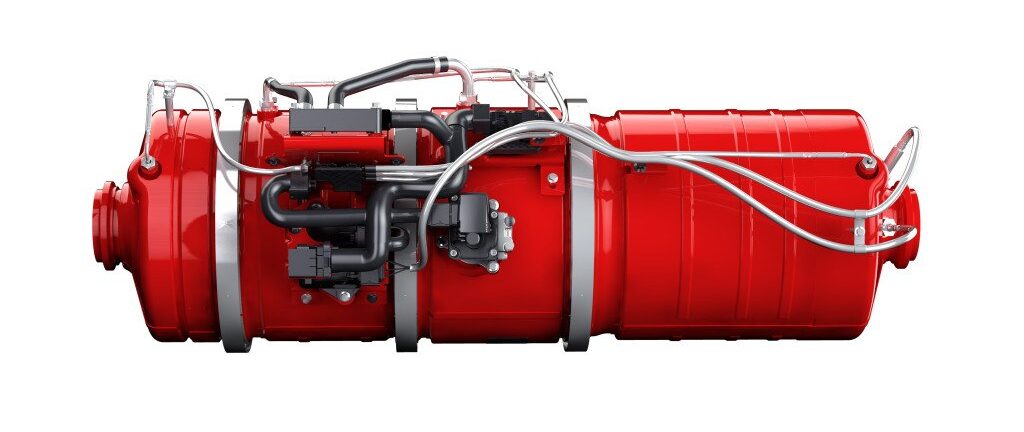

An SCR system does just that. It selectively targets NOx in the exhaust gasses and reduces them through a catalytic process, hence the system’s name: Selective Catalytic Reduction and the acronym SCR.

The SCR selectively targets NOx in the exhaust gasses and reduces them through a catalytic process, hence the system’s name: Selective Catalytic Reduction and the acronym SCR.

How do SCR systems work? What chemical reactions take place inside the catalyst?

As the exhaust gasses leave the turbocharger housing and head towards the SCR catalyst, they are mixed with Ammonia (NH3) which is produced by the injection of AdBlue. Once Ammonia and NOx find themselves in the SCR catalyst, the catalyst’s precious metal coating and the high temperatures, help to start a chemical reaction:

NO and NO2 (NOx) molecules react with Ammonia (NH3) and Water (H2O), then separate to Nitrogen (N2), Oxygen (O2) and Hydrogen (H) and start forming new bonds.

Due to some other chemical reactions which previously took place, we also have presence of Carbon (C).

The free Oxygen, Hydrogen, Carbon and Nitrogen molecules form new bonds. At the SCR catalyst outlet we measure:

- Water (H2O)

- Carbon Dioxide (CO2)

- Nitrogen (N2)

Are Diesel engines clean?

Diesel engines have come a long way the last 15 years and are cleanest than ever before!

Why do manufacturers stop the development of Diesel engines, then?

There is big noise in the media about this. Some (automotive/car/light vehicle – you name it!) manufacturers change their focus from Diesel to gasoline (petrol), hybrids or electric motor development.

But let me ask you this:

How many applications rely on diesel power?

Let me do the thinking for you: marine, locomotives, goods transport via trucks, construction machinery, mining machines, power generators, buses, agricultural machines and the list goes on…

So yes, it is true. In some years it will be difficult to find a new car with a diesel engine. But Diesel is here to stay, especially on many other sectors apart from passenger cars.

Closing…

Hopefully you’ve gained a better understanding on SCR systems now! If you would like more information about it, I have some more posts on the works which I will be releasing soon.

If you want to stay up-to-date when they will be released, please consider subscribing to the newsletter. Your privacy is important, that’s why I personally guarantee you, you will never receive any spam from me. The newsletter contains updates about new posts and new training courses that become available.

Many thanks for taking the time to read the post.