Non-Common Rail Diesel engines vs. Modern Diesel Common Rail system technology

When we hear these two words: “Diesel engine”, most of us immediately picture a cloud of black smoke and noise!

Things have changed a lot since the old days. It always used to be a matter of injecting more fuel and squeezing as much air as possible into the cylinder.

That’s a great solution to get maximum power from the engine! However, in our days, this is environmentally (and in general public opinion also socially) unacceptable.

My personal position

Before my intentions are misinterpreted, I need to clarify my position.

Provided that an engine meets the manufacturer’s specifications and the emission levels it was designed to comply with, I am OK with the fact that it might smoke. This is a design intention at the time of manufacture.

I am NOT OK when people intentionally manipulate an engine in any way, in order to deviate significantly from the original specifications. Especially the ones related to emissions! I totally DO NOT agree with EGR delete, DPF delete, or any other method where the modified engine fails to meet the emission certification for that particular model.

Non-common rail Diesel Combustion

Coming back to our subject, let’s analyse the combustion process in an older Diesel engine:

Typically, a Diesel pump supplies fuel to each injector separately, or some times the injector is a mini-pump.

The pump is timed to the engine and provides fuel under pressure to the right injector, at the right time. Here’s a breakdown of the process:

- The injector’s needle valve is held down with the help of a spring.

- Fuel under pressure reaches the injector (the pressure acting on a surface becomes a force).

- The force acts on the needle and has a direction opposite to the spring’s force.

- When the lifting force overcomes the spring force, the needle valve lifts, and fuel flows out of the small injection orifices.

- Injection stops when the fuel pressure reduces and the spring force becomes greater than the lifting force.

The whole process I described above lasts a few milliseconds. The combustion cycle completes with a violent, one-off explosion which stresses the engine components enormously. That’s where the characteristic Diesel engine noise (“Diesel knock”) is coming from. People also characterize Diesel engines as running harsher compared to gasoline engines. And then comes Common Rail!

What makes a Common rail engine more civilized?

To start with, the ability to accurately control the injection process.

Did you know that some injectors can inject up to 7 times during one combustion event? Compare that with an old-school injector (one injection…)!

A typical combustion process in a common rail Diesel engine has a minimum of 3 injections per combustion cycle:

- Pre-injection: Reduces “diesel knock” by injecting a small fuel quantity before the piston reaches the Top-Dead-Center (TDC). The small quantity of fuel self-ignites and prepares the cylinder for the main injection. The cylinder Temperature and Pressure increase.

- Main injection: Happens just after the TDC. This is the main injection quantity. Sometimes it is split into two parts.

- Post-injection: Controls emissions. It happens before the Bottom-Dead-Center (BDC). The ignition of the fuel injected during the post-injection cycle, helps burn off the last unburned Diesel droplets of the main injection.

A common rail engine requires an engine management system.

So, the reason that a common rail engine runs smoother than a traditional “old-school” engine lies to the fact that the ECU does all the calculations to accurately control injection down to the split-second and achieve maximum power while keeping the mechanical stress (and noise) to the minimum.

How does the Engine Management System control Diesel injection?

The engine management system needs an Engine Control Unit (ECU – also referred to as ECM or Engine Control Module) which:

- collects various inputs from sensors,

- identifies the next injector to inject fuel,

- calculates the time required to keep the injector open (opening duration = fuel quantity),

- commands the injector to inject based on the calculated parameters

- commands injector to stop injecting.

The process is not complete, but if you have no experience on common rail or engine management systems, it’s enough to get your thoughts started!

There are numerous other factors which I did not mention. Just to name a few other things the ECU is concerned about:

- What’s the engine speed? (RPM)

- What’s the coolant Temperature?

- Throttle pedal position?

- Incoming air temperature?

- Air pressure in the intake manifold?

- Are exhaust gasses being recirculated? (EGR position)

- What is the rail pressure right now? (measured)

- What should the rail pressure be? (calculated/theoretical)

- …and the list goes on!

Common Rail Diesel injection sensors

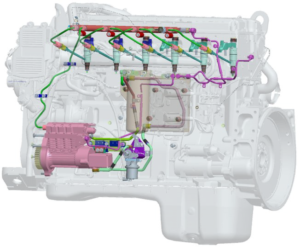

A typical common rail system needs the following sensors as a minimum:

| Sensor | Function | What does it affect? |

| Engine speed sensor | Measures the RPM of the crankshaft | Fuel quantity and Injection duration based on the available timing window (high RPM = less time available) |

| Engine position sensor | TDC position of Cylinder No. 1 and subsequent positions of the other cylinders | Injector/Injection sequence |

| Intake manifold pressure sensor | Measures the air pressure in the intake manifold. Higher pressure = more air = more oxygen available for combustion | Injection Fuel quantity |

| Intake manifold temperature sensor | Measures the air temperature in the intake manifold. Higher temperature = expanded air = less oxygen available for combustion | Injection Fuel quantity |

| Common Rail pressure sensor | Measures the pressure in the common rail | Injection Fuel quantity |

| Throttle pedal position sensor | Measures the pedal’s position | Injection quantity based on throttle pedal position (driver demand) vs. current engine conditions (current operation) |

| (optional) Mass Air Flow sensor | Measures the air flow at the intake manifold | Injection Fuel quantity |

Common Rail Diesel injection actuators

Typical actuators utilized in Diesel Common-Rail systems are:

| Actuator | Function | What does it affect? |

| High pressure Diesel pump actuator | Electronically controlled valve acting as a restriction to fuel flow | Rail pressure. Valve fully open = more fuel reaching the pumping chambers = higher output flow from pump-to-rail = higher rail pressure Valve restricting flow (not fully blocking it) = less fuel reaching the pumping chambers = lower output flow from pump-to-rail = lower rail pressure |

| Injector | Injects fuel into the combustion chamber | Emissions and power! |

Common Rail system typical pressures

Health and Safety warning! Seriously. I cannot stress this enough.

Did you know that fuel at 2 bar pressure (29 psi) coming out of a small orifice (hole), can penetrate human skin?

Now compare to this:

The typical pressures inside a Diesel engine common rail are:

- Engine Idle (about 700 RPM) or no load: ranging from 250 bar to 350 bar (3,626 psi to 5,076 psi)

- Maximum operating pressure: This varies depending on the system. Typical breakpoints are:

- 1600 bar (23,200 psi)

- 1800 bar (26,100 psi)

- 2200 bar (31,900 psi)

Some systems (like the Cummins XPI on ISX15/QSX15 or ISL9/QSL9) are able to hold fuel rail pressure for an extended period of time, while the engine is not running. This can be several days or weeks! The latest ISB6,7 for example, holds a minimum of 500 bar (7250 psi) for a few days after key-off!

What does that mean?

If you suspect fuel leak, NEVER EVER use your fingers to verify a leak on the high pressure side! To ensure you keep your fingers attached to your hand, just use a piece of cardboard.

Do not try to repair the high pressure common rail system by removing components WITHOUT depressurizing the system, there is a high risk that fuel can escape under high pressure, causing injury or even death. Please get trained or read the manual before you attempt any repair on a high-pressure common rail system!

I will be happy to organize a webinar on request, on the basics or how to deal with various Cummins Common Rail systems (ISB/QSB 4.5 or 6.7, ISC8.3/QSC8.3, ISL9/QSL9, X12, ISX15/QSX15). If you are interested, please use the contact page or simply email me on contact@dieseltraining.net.

How sensitive is a Common Rail Diesel system?

To achieve high pressures and accuracy, components can have an internal manufacturing tolerance of 5 to 2 microns! That is 0.005 mm or 0.002 mm (0,0002 in. to 0,00008 in.)! Did you know that the size of some bacteria is about 5 to 1o microns?

Any contamination from dirty fuel or by bad repair practices, can damage the internal surfaces of a component (eg. injector), causing it to deviate from its original specifications.

If you need to work on a fuel system, please ensure you clean the high pressure components you need to work on and cover the openings that handle fuel with a clean cap. There are various kits in the market just for that purpose. Even a glove can minimize the risk (not the ones with anti-sweat coating!)

What tools do I need to diagnose a Common Rail system?

Common Rail fuel systems operate on hydraulic principles. The system delivers a specified fuel flow on certain engine load or certain common rail pressure. To determine if the sysetm works well, we need to measure fuel flow (generally speaking, quantity vs. time, like liters per minute) or system leakeage (tank return).

Typically you will need to be able to control the pressure with a diagnostic tool such as Cummins Insite (Cummins engine specific) or TEXA (really good and universal tool for engine diagnostics).

Then you will need to know the specifications of the system you are working on.

If you work on Cummins engines, I’ve got you covered! I can arrange a training session tailored to YOUR needs via a webinar tool (Like Zoom or Microstoft Teams). You will also need a Cummins QuickServe Online account to be able to access the workshop manual. Here’s how to create one account for FREE.

Lastly, you will need some diagnostic tools like hoses, pressure gauges, or test kits.